PRODUCTS

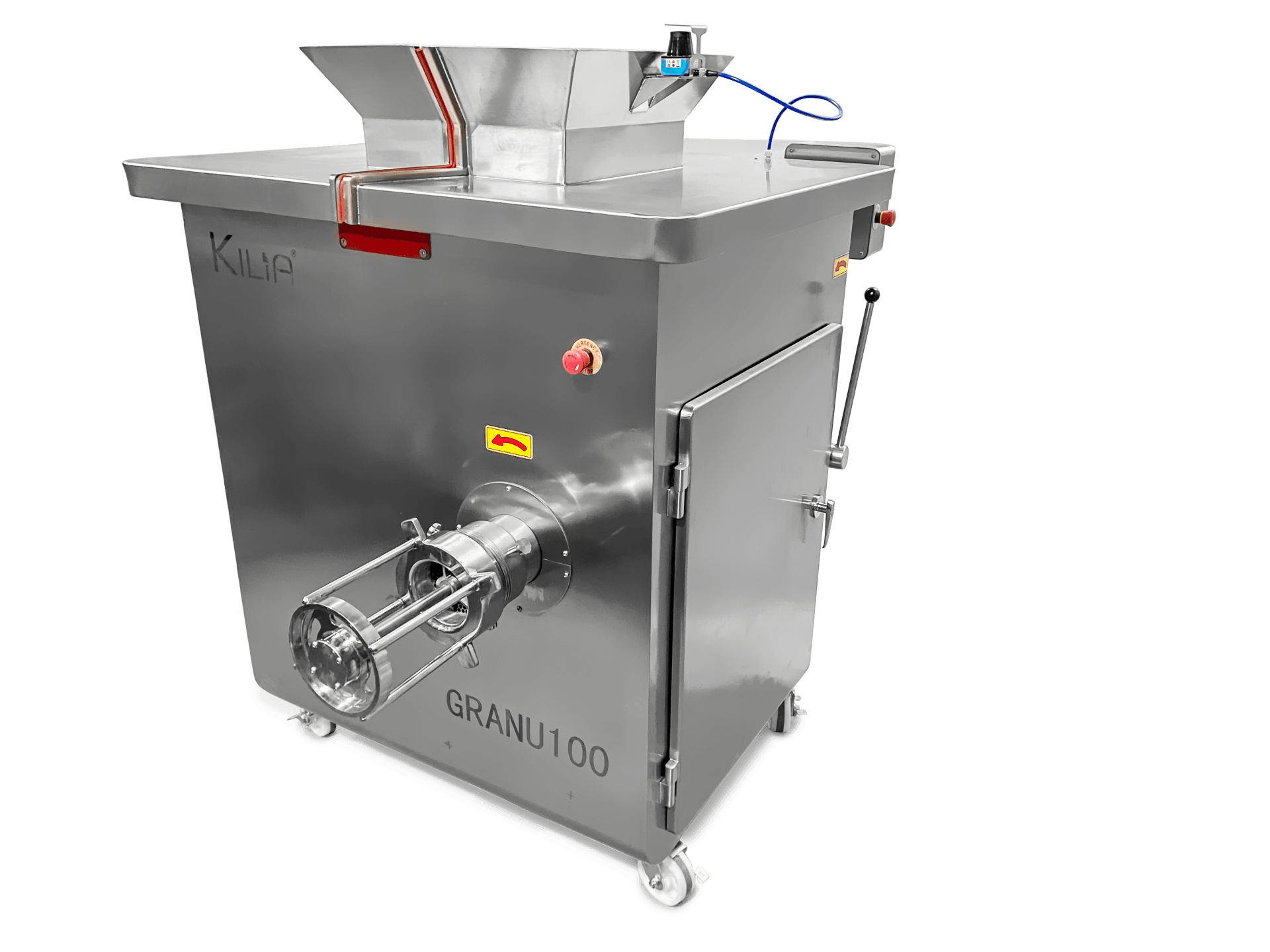

GRANU 100

The perfect R&D machine

Granulating capacity up to 2 tons / h

Machines with an Automatic Cleaning System available

GRANU 200

The machine for a medium capacity

Granulating capacity up to 6 tons / h

- Ventilation System for cooling

- Machines available with an Automatic Cleaning System

- can be integrated in Kilia PLCM (Industry 4.0)

GRANU 300

The machine for the large capacity

Heavy duty industry machines working

24 / 7 / 360:

Granulating capacity up to 17 tons / h

- Ventilation System for cooling

- Heavy duty gear motor system

- Machines available with an Automatic Cleaning System

- can be integrated in Kilia PLCM (Industry 4.0)

PreCutter 1500

Heavy duty industry machines Working

24 / 7 / 360:

FAQs

Where is Kilia located?

Kilia is based in Germany, and serves clients around the world with engineering, installation and support services.

What makes Kilia technology unique?

Over 90 years of German engineering expertise combined with AI-based PLCM control, automated cleaning systems and precision-built machines set Kilia apart.

What role does Kilia machinery play in SAP production?

Kilia machines are a vital part of the Super Absorbent Polymer (SAP) production process. They are used for granulating, mixing, and particle size adjustment, transforming continuous polymer bands from band reactors into a fine and uniform structure that is much easier to dry and further process.

Why is granulation a crucial step in SAP manufacturing?

During SAP production, continuous polymer strands or sheets are created. Granulation breaks these down into small, consistent particles, significantly improving drying efficiency, reducing energy consumption, and ensuring stable product quality for downstream processes such as sieving, surface treatment, and packaging.

Can Kilia machines handle large-scale industrial production?

Absolutely. Our equipment is built for extreme industrial use and operates reliably in SAP factories worldwide 24 hours a day, 7 days a week, 365 days a year. Many of these plants produce up to 60,000 tons of SAP per year, demonstrating the durability, reliability, and performance of our technology under continuous heavy-duty conditions.

Can the granulation process be tailored to specific SAP requirements?

Yes. We offer customized granulation solutions tailored to your raw materials, desired particle size, throughput, and production parameters — ensuring seamless integration into your existing SAP manufacturing line.

Are Kilia machines compliant with safety and quality standards?

Yes. All Kilia equipment is designed and manufactured in compliance with the latest EU directives and meets international quality and safety standards for chemical and polymer production environments.

How long has Kilia been involved in SAP production?

Kilia machines have been part of SAP manufacturing since 1969. With over five decades of experience, we bring deep industry know-how and proven technology to some of the world’s most demanding SAP production lines.